Neuigkeiten31 Mai 2024

Aluminium and stainless steel diesel tanks for overland trucks

About 6 months ago, we swapped our two painted steel tanks to one aluminium and one stainless steel tank

We are already noticing differences in how the two materials perform in everday-overland use.

In the mentioned time span we have been traveling on the Carretera Austral in Chile, the Argentine Patagonia and Tierra del Fuego.

Here we encountered endless gravel roads and coastal areas with the influence of saltwater, as well as icy temperatures.

The two materials may look similar, but they’re quite different. So we will try to list a couple of differences between the aluminium and stainless steel tank:

- Strength to weight ratio: Aluminium is about one third of the weight of stainless steel, but not as hard.

- Corrosion: Stainless steel offers ultimate corrosion resistance because its metallurgic structure, and this is reach due to the presence of elemen like Chromium. Aluminium, has a passivation layer of oxide, which slows further oxidation and corrosion. So basically, both materials are a good choice.

- Weldability: tarting from the premise that our analysis focuses on possible serious damage due to impacts and cracks caused by rough terrain and extreme conditions, stainless steel is certainly relatively easy to weld even for those working in non-professional contexts. However, it must be kept in mind that we must be careful of the fact that the inside of the tank will be covered by a layer of diesel fuel and will therefore necessarily have to be cleaned.

In very remote areas, therefore, it may be more difficult to find a welder for aluminium because the work involves specific equipment and a high cleanliness level in the location. This also leads us to emphasise how important is the overall quality of tanks and expertise in robotic welding as well as quality control processes.

In the end, we believe stainless steel is the most suitable material for overland repairs. At the same time, we opted for painted steel tanks on our first trip and have been our partners for several years.

- Everyday use: we observe that our aluminium tank has more scratches, whereas the stainless steel tank only gets very superficial, small scratches. Exposed to the elements, the difference is also visible: the aluminium tank has started to form its so-called passivation layer, while the stainless steel tank remains nearly as new.

It may sound like the Stainless Steel Tank is the one to choose, but the Aluminium Tank with its weight benefit, corrosion resistance and durability is also a very appealing choice.

In the end it’s all about the individual needs for your vehicle.

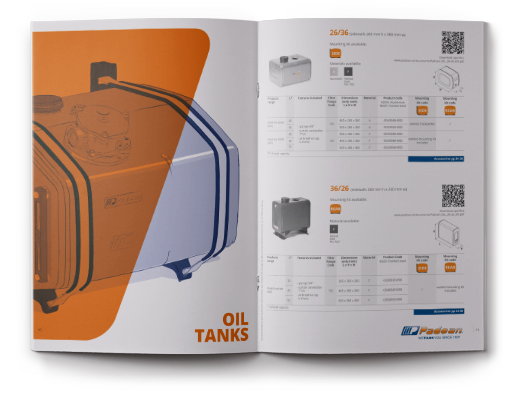

Speaking of individual needs, we really appreciate that Padoan has a big selection of sizes of tanks. In our case for example, we chose a tank that is wider and higher but shorter than the original tank, but it’s the same volume of fuel.

This gave us an extra 25cm on each side of the chassis, which allowed us to use the space more efficiently and we were able to mount two extra storage boxes on our truck.

Laden Sie unsere

Unternehmensbroschüre herunter

Entdecken Sie unseren Katalog mit allen Details zu unseren Produkten.

PDF HERUNTERLADEN