News28 April 2022

A partner for OEMs and upfitters

The tank is the heart of the system, and there is no doubt that its volume is crucial to optimising space and achieving maximum efficiency.

WHEN TO THINK ABOUT THE TANK

On the one hand it is necessary to consider the pump’s capacity and the technical requirements related to the speed of suction and return of the fluid, but at the same time it is necessary to deal with an increasing need to rationalise the overall dimensions.

However, the reservoir is often only considered at the final stage, when the design of applications, systems and machinery is finalised.

This leads to the need to find extremely customised solutions that can achieve the balance between the quantity of fluid required and the use of the volumes that remain accessible.

This means creating shapes and volumes that exploit the often irregular space left available.

IRREGULAR TANK: WHICH IMPLICATIONS?

Creating irregular volumes and shapes brings with it many aspects to consider from a functional point of view, including:

– The consistency of the suction and return flow,

– The need for cooling of the hydraulic fluid,

– The possible future need for replacement.

Other important points to consider, related to tank manufacturing and logistics are:

– The internal cleanliness determined by manual welding,

– Production schedules,

– The size of the warehouse dedicated to tanks for production and spare parts.

Last but not least, especially when it comes to vehicle applications, is the material used.

Painted carbon steel or stainless steel are often chosen for their ease of welding compared to aluminium, but with the added disadvantage of weight, particularly during installation.

Ease of replacement is also in favour of more standardised shapes and more industrialised processes, for speed in producing spares if required.

WHY SHAPE MATTERS

The tanks produced manually and with very irregular shapes take advantage of the space, but do not facilitate the circulation of the fluid and therefore its cooling, and it should also be considered that the metal sheet with a considerable thickness has as a consequence a lower thermal dissipation.

At Padoan we have always been committed to proposing tanks with regular shapes, in particular starting from the side bottom.

The decision to pursue this path is driven by the will to preserve the application.

This is done since the production stage with the robotized MIG/MAG welding, which allows an outstanding internal cleaning as well as a regular weld seam.

The resulting shape, squared with rounded corners, facilitates the flow and at the same time stabilises the fluid by avoiding emulsions, which are frequent when the fluid breaks into the tank and hits uneven walls.

At the same time, the fluid is preserved thanks to wide surfaces that facilitate heat exchange for cooling.

HOW TO OPTIMISE THE DESIGN

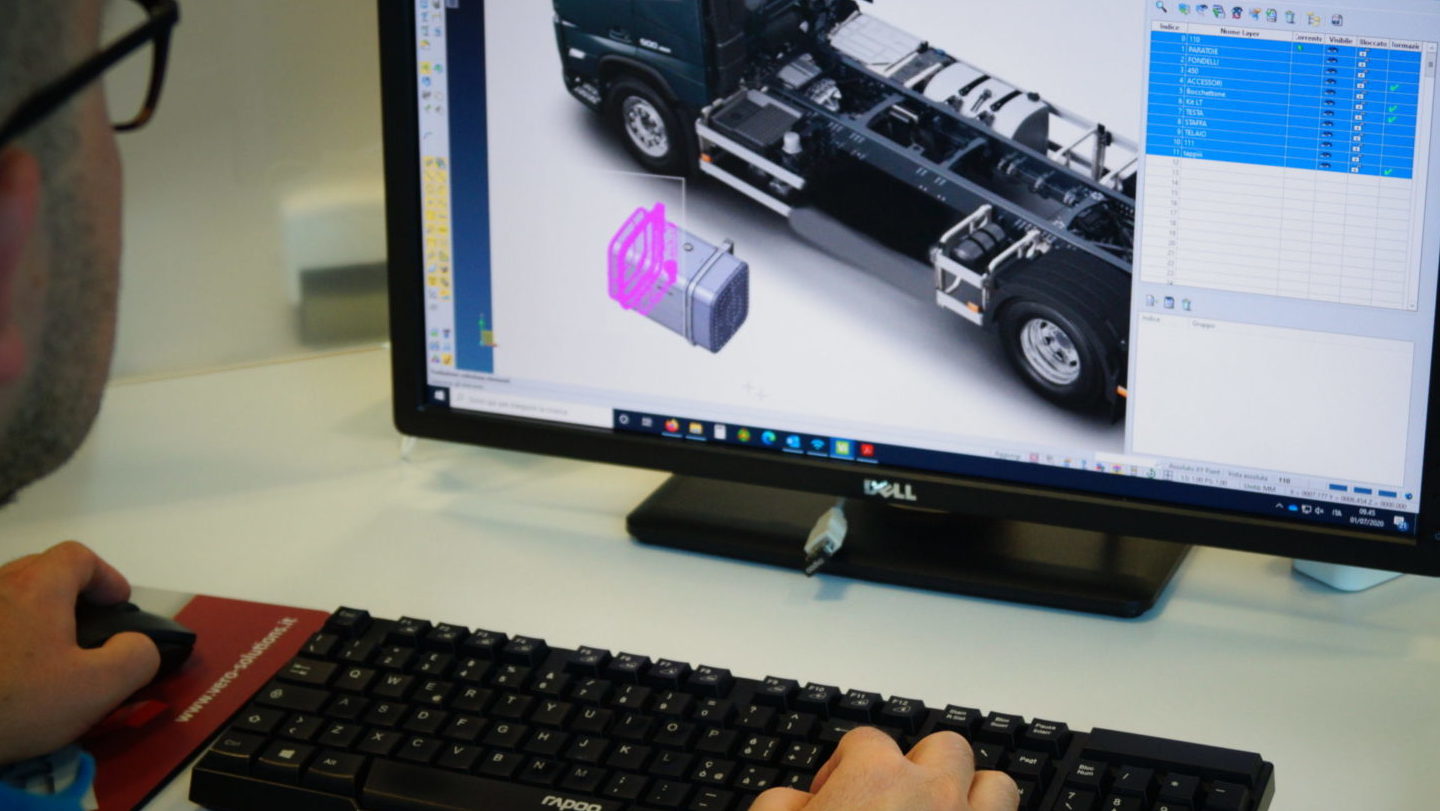

The engagement of Padoan by manufacturers and outfitters of vehicles, applications and machinery is increasing, requiring our support since the design process of the comprehensive system.

The Research and Development team integrates, with different degrees according to the needs and wishes of the customer, in the technical and design team, providing answers, opportunities and solutions.

This allows the customer to fully benefit of the solutions already designed by Padoan according to specific applications and to obtain, at the same time, customizations related to suction, returns, filtration, accessories and dedicated components.

THE AESTHETIC ASPECT DEFINES THE VALUE

Finally, one aspect that should not be overlooked is the aesthetic aspect. It is not just a question of appearance, but also of consistency.

A machine, a vehicle or an application needs care for the details, which must be in line with and give a clear idea of the technical precision, functionality and advantages of choosing a brand and a product over others.

PARTS, TIMING, VALUE CHAIN OPTIMISATION

Many aspects are involved in the development of a new application, a vehicle or a machinery, and certainly one aspect to be considered is the supply chain. Using a Padoan hydraulic tank also means being able to count on constant delivery times, order planning and, if required, also on collateral services that support the logistics and purchasing functions with flexibility.

Contact us and find out how we can support you in the development of your application.

Download our

company brochure

Discover our catalogue, with all the detailed information about our products.

Download PDF